Press release from Cincinnati Incorporated Century-old machine tool builder shows it still has innovation in its DNA with BAAM system, offers industrial-sized 3D printing 116-year-old Cincinnati Incorporated debuts its industrial-sized 3D printing technology, to rave reviews at North America’s largest machine tool trade show; looks to revolutionize large-part manufacturing, as it did laser cutting more than 30 years ago. (Harrison, Oh.) - Cincinnati Incorporated reinvented laser cutting of sheet metal when it introduced the first machine with flying optics and dual pallets in 1986, followed by its high-speed linear motors in 1996. Today, the company is writing history with the rollout of the first Big Area Additive Manufacturing (BAAM) system, taking 3D printing to a large, industrial scale. With a historic demonstration of never-before-seen capability, the new BAAM machine created a car body as if out of thin air, and in a matter of hours, at IMTS 2014 in Chicago. Cincinnati Incorporated, in conjunction with the Department of Energy’s Oak Ridge National Laboratory (ORNL) and Local Motors, printed and assembled the world’s first 3D-printed car during the tradeshow. The large-scale additive machine uses the chassis, drives and control of Cincinnati’s laser cutting system as the base, and extrudes hot thermoplastic to build parts, layer by layer. The machine, developed as part of a cooperative research and development agreement between Cincinnati Incorporated and ORNL, introduces significant new manufacturing capabilities to a wide range of industries including automotive, aerospace, appliance and robotics. “We seem to have a knack for developing game-changing innovations,” said Andy Jamison, CEO of Cincinnati Incorporated. “We’ve already sold our first BAAM machine, and we have other prospects in the pipeline as a result of the demonstration at IMTS, so the machine and technology have been very well-received.” One word: plastics The first BAAM sale was to SABIC Innovative Plastics, the company that provided the carbon fiber ABS plastic for the IMTS car. The BAAM extruder uses a wide variety of thermoplastics and fiber reinforced thermoplastics and SABIC plans to test a number of materials that will meet the needs of a variety of commercial applications, including furniture and tooling. “SABIC, has already tested ABS, PPS, PEKK and Ultem, and we’re finding that carbon fiber and glass fiber reinforcing improve both the strength and thermal stability of the parts,” said Jamison. Big Now, Soon to be Bigger With a current work envelope of 2 x 4 x .87 m (6.6 x 13.1 x 2.9 ft) and extrusion rate of about 38 lbs/hr, the machine prints polymer components up to 10 times larger than currently producible, at speeds 200 to 500 times faster than existing additive machines. And, plans are to go even bigger and faster. “We’re already working with ORNL to increase the work envelope to 2.4 x 6 m (8 x 20 ft) and with SABIC to increase the extrusion rate to 100 lbs/hr,” said Jamison. “Increasing the Z-axis travel (The working height for the part being built) is also a priority.” The BAAM machine is linear motor-driven, like the laser cutting system before it, allowing it to maintain a perfectly level bed required for proper 3D printing. For more information on the additive manufacturing initiative, contact Cincinnati Incorporated at 513.367.7100 or info@e-ci.com, or visit www.e-ci.com.

Friendship Fire Responds to Near Head-On Collision

Friendship Fire Responds to Near Head-On Collision

Kentucky State Police Investigating Officer-Involved Shooting Outside Amazon Facility

Kentucky State Police Investigating Officer-Involved Shooting Outside Amazon Facility

Indiana State Parks Offer Free Admission on May 4 for Welcome Weekend

Indiana State Parks Offer Free Admission on May 4 for Welcome Weekend

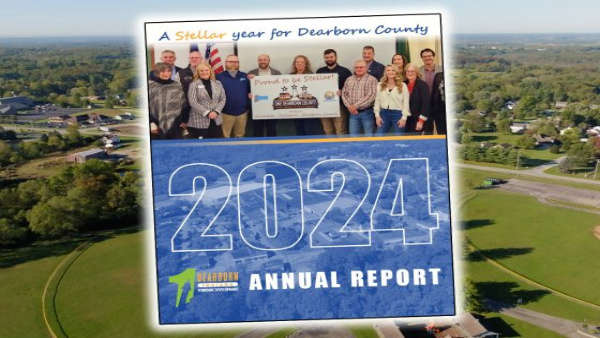

One Dearborn 2024 Annual Report Highlights Stellar Year for Dearborn County

One Dearborn 2024 Annual Report Highlights Stellar Year for Dearborn County

Indiana State Police K-9 Oswald to Get Body Armor Donation

Indiana State Police K-9 Oswald to Get Body Armor Donation

Louisville Man Facing Burglary, Rape, & Sodomy Charges in Boone County

Louisville Man Facing Burglary, Rape, & Sodomy Charges in Boone County